GE T

Hot Isostatic Pressing and AM: How to improve product quality and productivity for critical applications Metal Additive Manufacturing is rapidly gaining momentum across a broad range of industries and is often used for producing components for challenging applications such as medical implants and rocket engines. To maximise the mechanical strength and fatigue resistance of such critical AM parts, they must be processed by Hot Isostatic Pressing (HIP) to eliminate any residual porosity, and heat treated. Jim Shipley from Quintus Technologies provides an overview of HIP and High Pressure Heat Treatment technology for Powder Bed Fusion AM and considers the opportunities that a new generation of HIP equipment presents.

Over the past decade, metal Additive Manufacturing, and in particular Laser Beam Powder Bed Fusion (PBF-LB), has become an established technology in a number of industrial sectors. Without some of the limitations of traditional production methods, Additive Manufacturing has enabled engineers to design products with higher performance, lower production cost, longer service life, reduced weight, and a potentially reduced environmental impact. In parallel to the advancement of AM technology, methods to improve mechanical properties through post-processing have been adopted by the industry. Post-processing methods such as Hot Isostatic Pressing (HIP) and High Pressure Heat Treatment (HPHT™) can significantly improve durability and fatigue resistance while offering the potential for shorter overall production times. Companies in a wide range of industries are rapidly adopting this new technology, especially for use in critical applications in demanding

Vol. 9 No. 3 © 2023 Inovar Communications Ltd

industries such as automotive, aerospace, defence, energy and medical, where performance and safety are crucial. There are four technologies that will be covered in this article:

tion of oxidation, and alpha-case discolouration • Digitalisation

• High Pressure Heat treatment Technologies for the minimisa-

Understanding the benefits offered by these technologies allows manufacturing companies to optimise their production, improve product performance, and reduce cost.

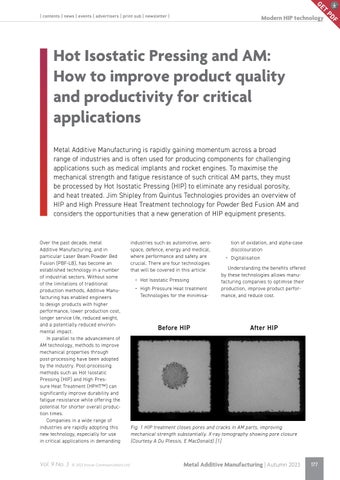

Before HIP

After HIP

• Hot Isostatic Pressing

Fig. 1 HIP treatment closes pores and cracks in AM parts, improving mechanical strength substantially. X-ray tomography showing pore closure (Courtesy A Du Plessis, E MacDonald) [1]

Metal Additive Manufacturing | Autumn 2023

177

F

Modern HIP technology

PD

| contents | news | events | advertisers | print sub | newsletter |